Showing 409–420 of 632 results

-

- Exceptional Catalytic Properties: Platinum is one of the most efficient catalysts, facilitating numerous chemical reactions in the automotive, chemical, and energy industries.

- High Electrical and Thermal Conductivity: Makes platinum ideal for electronic and thermal applications.

- Corrosion and Oxidation Resistance: Platinum resists corrosion and maintains its integrity even in harsh environments.

- High Stability: Performs well at elevated temperatures, making it suitable for extreme conditions.

- Hydrogen Absorption: Platinum is highly effective in processes involving hydrogen storage and purification.

-

- Chemical Resistance: PTFE is highly resistant to a wide range of chemicals, including acids, bases, and solvents, making it ideal for corrosive applications.

- Non-Stick Surface: The material’s low surface energy allows for the production of coatings that resist adhesion, which is beneficial in various applications.

- Electrical Insulation: Excellent dielectric properties make it a great choice for insulating electrical components.

- High Temperature Resistance: PTFE can withstand a broad temperature range, maintaining its performance even at high temperatures.

- Durable Coatings: PTFE sputtering targets produce uniform and durable coatings with low friction and high wear resistance.

-

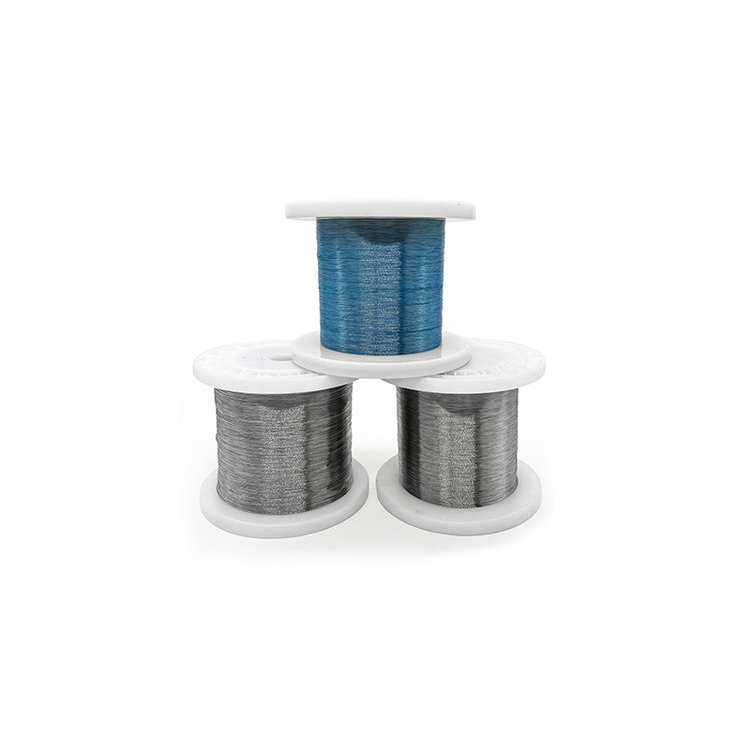

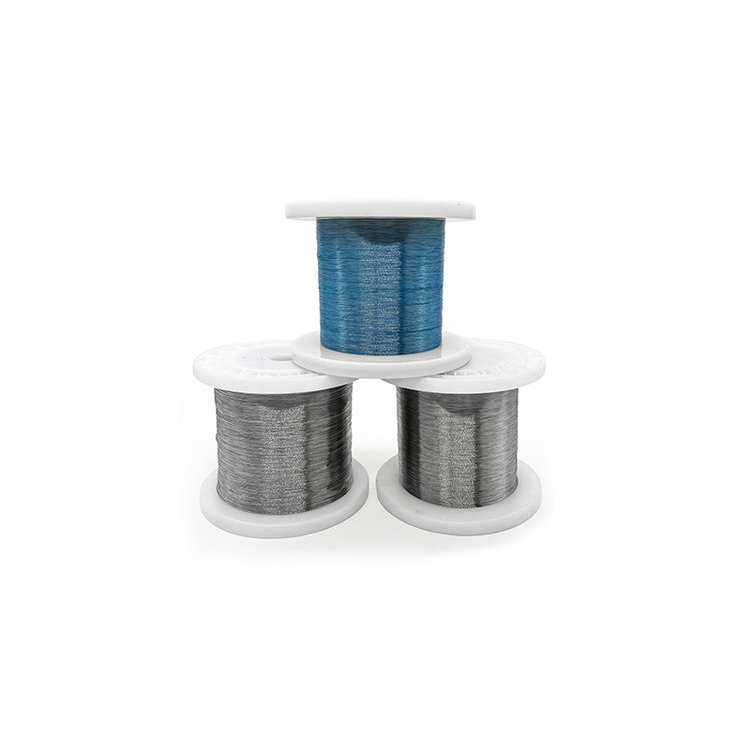

- High Melting Point: The platinum-iridium alloy has a high melting point (1,768°C for platinum and 1,410°C for iridium), making it suitable for use in high-temperature environments without degrading.

- Excellent Corrosion and Oxidation Resistance: Platinum-iridium wires exhibit remarkable resistance to oxidation, corrosion, and chemical degradation. They maintain their integrity in harsh environments, including exposure to acids, high-temperature oxidation, and aggressive chemicals.

- Superior Electrical Conductivity: Platinum-Iridium wires provide excellent electrical conductivity while maintaining stability under high temperatures. This makes them ideal for high-precision electrical applications, such as thermocouples and resistors.

- Thermal Stability: With low thermal expansion and high thermal stability, platinum-iridium wires perform well across a broad temperature range, making them ideal for high-temperature applications like sensors and thermocouples.

- Mechanical Strength: The combination of platinum and iridium provides high mechanical strength and hardness, enabling platinum-iridium wires to withstand heavy-duty use without bending or breaking easily.

- Non-Toxic and Biocompatible: Platinum-iridium alloys are biocompatible and non-toxic, making them suitable for medical devices and applications where material safety is crucial.

- Durability and Longevity: Due to their outstanding resistance to corrosion and wear, platinum-iridium wires can last significantly longer than many other metals, reducing maintenance costs and increasing reliability in critical applications.

-

- High Piezoelectric Coefficient: Enables efficient conversion of mechanical energy to electrical energy and vice versa.

- Stable Dielectric Properties: Ensures reliable performance in high-frequency applications.

- Customizable Compositions: Tailored Zr/Ti ratios to meet specific functional requirements.

- High Purity and Uniformity: Ensures consistent film deposition with minimal defects.

- Versatile Deposition: Compatible with RF and DC magnetron sputtering systems.

-

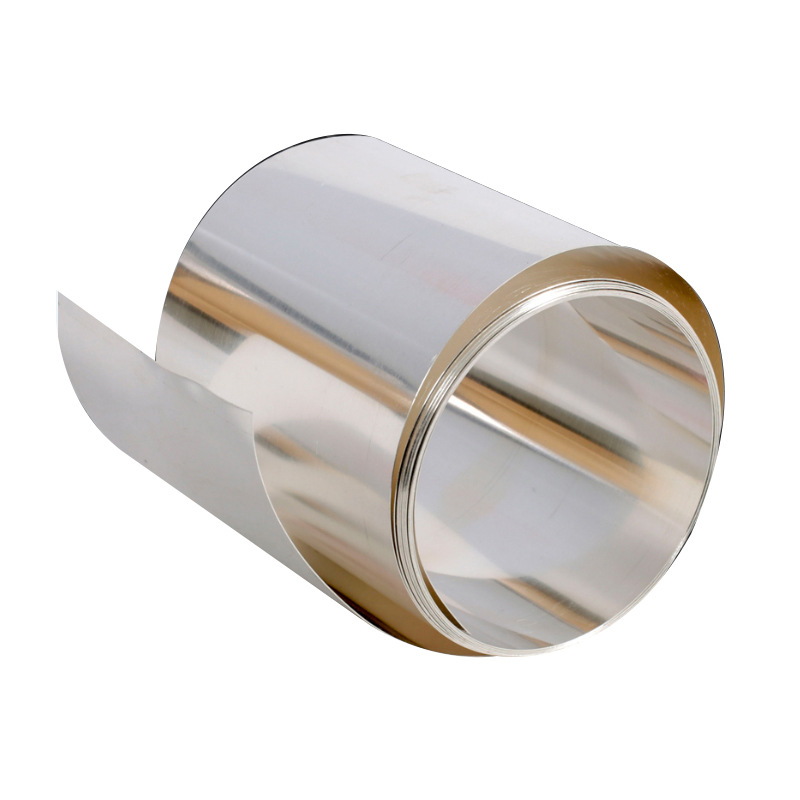

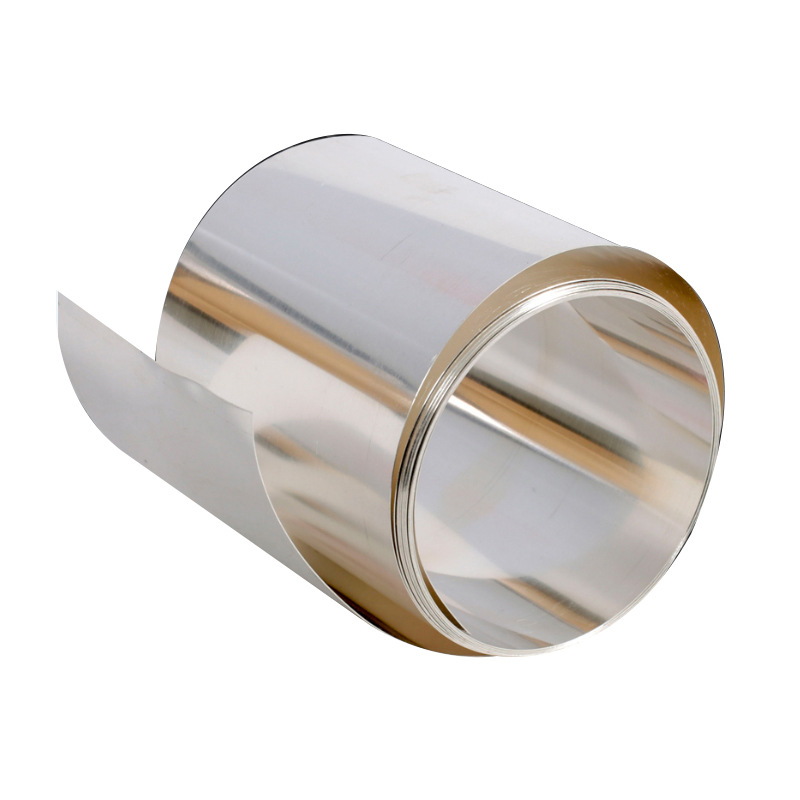

- High Melting Point: Rhenium has an extremely high melting point of 3180°C, making it ideal for use in environments with intense heat.

- Excellent Corrosion and Oxidation Resistance: Rhenium foil shows outstanding resistance to oxidation and corrosion, even at high temperatures.

- High Density and Strength: Known for its superior density and strength, rhenium foil maintains structural integrity under heavy loads and extreme temperatures.

- Thermal and Electrical Conductivity: Rhenium exhibits excellent thermal and electrical conductivity, making it suitable for high-performance applications in electronics.

- Malleability and Ductility: Despite its strength, rhenium foil can be easily processed, providing flexibility in various manufacturing processes.

-

- Extremely High Melting Point: Rhenium has a melting point of 3,186°C, making it ideal for applications involving extreme temperatures.

- Excellent Thermal Stability: Rhenium maintains its structural integrity and electrical conductivity at high temperatures, making it suitable for demanding applications.

- Corrosion and Oxidation Resistance: Rhenium offers high resistance to oxidation and corrosion, ensuring durability in harsh environments.

- Superior Mechanical Strength: Rhenium thin films are strong and stable, providing long-lasting performance in extreme conditions.

- Good Electrical Conductivity: Rhenium’s conductivity makes it suitable for high-performance electronic applications.

-

- High Melting Point: Rhenium has one of the highest melting points of any element (3,180°C), making it ideal for high-temperature applications.

- Exceptional Heat Resistance: Retains its mechanical properties and structural integrity in extreme thermal environments.

- Corrosion Resistance: Excellent resistance to oxidation and corrosion, especially at elevated temperatures.

- Alloying Element: Enhances the performance of superalloys and refractory metals, improving their strength, creep resistance, and overall stability.

- Catalytic Efficiency: Rhenium is highly effective in catalytic processes, particularly in the petrochemical industry.

-

- High Purity: Rhodium pellets are typically offered at 99.95% (3N5) or higher purity, ensuring that the deposited films are free from contamination, which is vital for semiconductor and optical applications.

- Excellent Reflectivity: Rhodium’s high reflectivity, particularly in the visible and infrared spectrum, makes it ideal for coatings on optical instruments and reflective surfaces.

- Corrosion and Oxidation Resistance: Rhodium’s chemical inertness ensures that coatings remain untarnished and resistant to environmental degradation, even under extreme conditions.

- High Melting Point: With a melting point of 1964°C, Rhodium is suitable for use in high-temperature evaporation systems.

- Uniform Coatings: Rh Pellets provide consistent evaporation, enabling the deposition of uniform and high-quality thin films on various substrates.

-

- High Corrosion Resistance: Rhodium is impervious to most acids and does not tarnish, even in harsh environmental conditions.

- High Melting Point: Rhodium has a melting point of 1,964°C, making it ideal for high-temperature applications.

- Excellent Reflectivity: Rhodium is one of the most reflective metals, making it ideal for coating applications where a bright, mirror-like finish is desired.

- Catalytic Efficiency: Rhodium is a highly effective catalyst in chemical and automotive industries, especially in emission control.

- Durability: Rhodium coatings are highly durable, resistant to scratching, and provide long-lasting protection.

-

- Excellent Reflectivity: Ideal for optical and decorative applications.

- High Corrosion Resistance: Suitable for harsh environments and chemical exposure.

- Superior Thermal Stability: Ensures performance under high temperatures.

- High Conductivity: Reliable for electronic applications.

- Customizable Configurations: Available in various sizes, purities, and bonding options.

-

- High Purity: Ruthenium pellets are available in 99.95% (3N5) or higher purity, ensuring minimal contamination during thin-film deposition, critical for semiconductor and optical applications.

- Excellent Corrosion Resistance: Ruthenium’s resistance to corrosion and oxidation makes it highly durable, extending the lifespan of coatings in harsh environments.

- Stable Electrical Conductivity: Ruthenium maintains consistent conductivity even at high temperatures, making it ideal for electronic applications requiring stable performance.

- High Melting Point: With a melting point of 2334°C, Ru is suitable for use in high-temperature evaporation systems.

- Hard and Durable Films: Ruthenium thin films are known for their mechanical strength, scratch resistance, and ability to withstand environmental degradation.

- Uniform Deposition: Ru pellets are designed for consistent evaporation, providing uniform thin-film coatings in various deposition systems like thermal evaporation or electron beam evaporation.

-

- High Chemical Stability: Ruthenium is resistant to most acids and does not corrode or tarnish easily, even in aggressive environments.

- Excellent Conductivity: With high electrical conductivity, ruthenium is widely used in electronic components like resistors and electrical contacts.

- Catalytic Activity: Ruthenium is an efficient catalyst in a range of chemical reactions, from hydrogenation to ammonia synthesis, and is particularly useful in fuel cells and renewable energy applications.

- Wear Resistance: Ruthenium coatings are exceptionally hard and wear-resistant, which increases the lifespan of coated surfaces in demanding applications.

- Improved Alloy Performance: When alloyed with other metals, ruthenium enhances hardness, corrosion resistance, and mechanical strength.