Showing 37–48 of 632 results

-

- Enhanced Strength: The addition of silicon increases tensile strength and hardness.

- Good Fluidity: Excellent flow properties make it suitable for casting and evaporation processes.

- Corrosion Resistance: Offers good resistance to oxidation and chemical exposure.

-

- High Strength-to-Weight Ratio: AlSi10Mg powder delivers a high strength-to-weight ratio, making it suitable for lightweight but robust components.

- Excellent Corrosion Resistance: Offers superior resistance to corrosion, ideal for use in harsh environments.

- Good Castability: Provides excellent castability, ensuring high-quality results in additive manufacturing.

- Enhanced Thermal Conductivity: Offers good thermal conductivity, making it ideal for heat-dissipating applications.

- Low Shrinkage: Exhibits minimal shrinkage during the additive manufacturing process, ensuring high precision.

- Ease of Post-Processing: The material can be easily post-processed, including machining, anodizing, and surface treatment.

-

- Electrical Conductivity: The presence of aluminum and copper in the alloy enhances the electrical conductivity of the deposited thin films, making it ideal for semiconductor and electronic applications.

- Thermal Stability: AlSiCu alloy films exhibit excellent thermal performance, ensuring stability in high-temperature environments like semiconductor fabrication and automotive electronics.

- Mechanical Strength: Silicon contributes to the mechanical durability of the alloy, providing resistance to wear and cracking in thin films, which is essential in demanding applications.

- Corrosion Resistance: The alloy offers good resistance to corrosion, ensuring longevity in exposed environments, such as automotive electronics and solar cells.

- Customizable Size and Shape: AlSiCu sputtering targets can be produced in various forms, including discs, plates, and custom shapes, to suit different PVD systems and specific requirements.

-

- Improved Strength: Copper enhances the overall tensile strength and thermal stability.

- Excellent Conductivity: High electrical conductivity makes it suitable for electrical applications.

- Corrosion Resistance: Maintains performance under oxidative conditions.

-

- Low Friction: Tin provides excellent lubricating properties, reducing wear on components.

- Corrosion Resistance: Offers good protection against oxidation and corrosion.

- Versatile: Suitable for a range of applications in electronics and machinery.

-

- High Strength: The addition of vanadium significantly enhances the strength and hardness of the aluminum matrix.

- Lightweight: AlV powder provides a lightweight alternative to other high-strength alloys, making it ideal for aerospace and automotive applications.

- Good Corrosion Resistance: Offers excellent resistance to corrosion, suitable for harsh environmental conditions.

- Superior Machinability: The powder is easy to process, ensuring high precision and quality in final products.

- Enhanced Wear Resistance: The vanadium content enhances wear resistance, making it suitable for parts exposed to high friction or abrasive environments.

- Thermal Stability: Exhibits good thermal stability, allowing it to perform effectively in high-temperature applications.

-

- Lightweight and Strong: Combines low density with excellent mechanical properties.

- Superior Thermal Stability: Maintains integrity at elevated temperatures.

- High Oxidation Resistance: Ideal for extreme thermal and environmental conditions.

- Customizable Al-Y Ratios: Tailored to specific industry requirements.

- Versatile Particle Sizes: From nanoscale to micrometer ranges for diverse applications.

-

- High Thermal Stability: With its relatively low melting point and ability to withstand high temperatures, B₂O₃ is ideal for applications that require materials to perform in extreme thermal conditions.

- Chemical Durability: Anhydrous boron oxide is highly resistant to chemical degradation, making it suitable for use in harsh environments where other materials might fail.

- Optical Clarity: Its high refractive index and excellent transparency in the UV-visible range make it perfect for use in precision optical devices.

- Purity and Consistency: At Tinsan Materials, we ensure that our B₂O₃ meets strict purity standards, offering consistent performance across all industrial applications.

- Versatility: Anhydrous boron oxide is a multifunctional material, suitable for a wide range of industries, from glass manufacturing to electronics and catalysts.

-

- High Purity (≥99.999%) – Ensures superior performance in advanced applications.

- Uniform Granule Size – Available in various sizes for controlled processing.

- Excellent Electrical Properties – Essential for semiconductor applications.

- Stable and Consistent Quality – Produced under strict quality control.

- Customizable Options – Granule sizes and packaging tailored to specific requirements.

-

- High Purity: Gold foil is typically made from high-purity gold, often 99.99% pure or greater. The high purity ensures excellent performance in sensitive applications such as electronics and medical devices.

- Malleability and Ductility: Gold is one of the most malleable and ductile metals, which means it can be easily shaped or stretched without breaking. This property makes gold foil ideal for precise applications where flexibility and thinness are required.

- Excellent Electrical Conductivity: Gold foil has superior electrical conductivity, making it ideal for use in high-performance electronic devices such as connectors, semiconductors, and microelectronics.

- Corrosion and Oxidation Resistance: Gold’s natural resistance to corrosion and oxidation makes gold foil an excellent choice for applications exposed to harsh environments. It does not tarnish, rust, or corrode, ensuring long-term durability and reliability.

- Thermal Conductivity: Gold foil offers high thermal conductivity, which is useful in heat dissipation applications in electronic devices and aerospace technology, where managing heat is critical.

- Biocompatibility: Gold is biocompatible, meaning it is safe for use in medical and dental applications. It does not cause adverse reactions in the body, making it ideal for implants and other medical devices.

- Reflectivity: Gold foil has excellent optical reflectivity, especially in infrared wavelengths, making it valuable in specialized coatings and mirrors for scientific instruments, telescopes, and other optical applications.

-

- High Purity: Gold pellets are available with ultra-high purity levels (99.99% or higher), ensuring the quality and consistency of the thin films.

- Excellent Conductivity: Gold provides outstanding electrical and thermal conductivity, making it ideal for electronic components.

- Corrosion Resistance: Gold’s inertness ensures that it remains resistant to corrosion, tarnishing, and oxidation, even in harsh environments.

- High Reflectivity: Gold coatings are highly reflective, particularly in the infrared range, making them suitable for optical and thermal applications.

- Biocompatibility: Gold is non-toxic and biocompatible, making it a safe material for medical devices and implants.

-

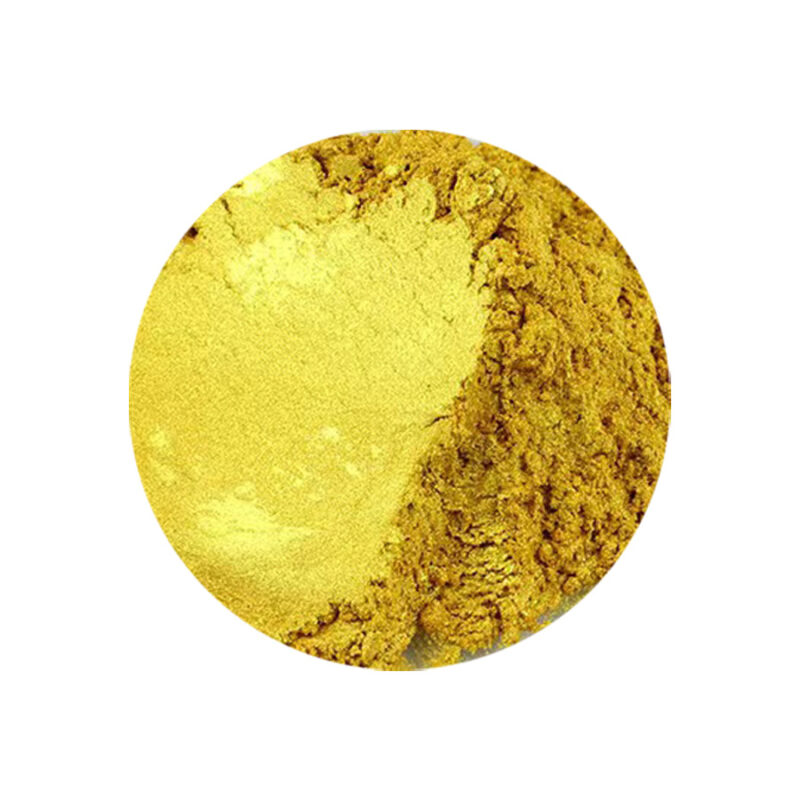

- Excellent Electrical Conductivity: Provides high efficiency in electronic applications.

- Corrosion Resistance: Gold’s natural resistance to oxidation ensures long-term stability.

- Biocompatibility: Safe for use in medical devices and cosmetics.

- Aesthetic Appeal: Bright, lustrous appearance makes it ideal for decorative applications.