PVD Consumables

Tinsan Materials provides a comprehensive range of high-quality components essential for PVD processes, including parts for E-Beam evaporators, ion sources, and thermal evaporators. These components play a critical role in ensuring the success of thin-film deposition processes by supporting the material evaporation and deposition operations.

Types of PVD Consumables

We offer several key consumables tailored for various deposition techniques:

Crucibles are essential containers used in E-beam and thermal evaporation systems to hold the evaporation materials (such as metals, alloys, or ceramics) during the deposition process. These components need to withstand high temperatures and prevent contamination of the evaporated material. The crucibles offered by Tinsan Materials are made from high-quality materials to ensure durability and consistency in the deposition process.

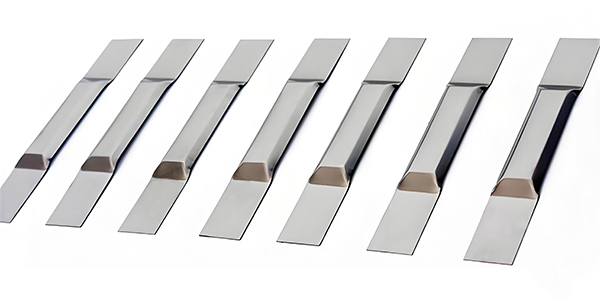

Boats are typically used for thermal evaporation systems. They hold the materials to be evaporated and transfer heat efficiently to achieve the desired vaporization. Tinsan Materials boats are carefully crafted to provide optimal thermal conductivity and prevent material degradation, ensuring a smooth evaporation process and high-quality coatings.

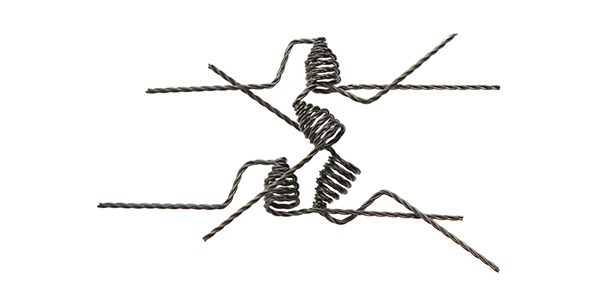

Filaments are used in both thermal and electron beam evaporation systems to heat and vaporize materials. They are designed to work efficiently at high temperatures and are made from durable materials that resist wear over time. Tinsan Materials filaments are manufactured with precision to deliver consistent performance in the evaporation process.

Custom Manufacturing for Specific Needs

One of the standout features of our offerings is the ability to provide custom manufacturing for these consumables. Depending on specific customer needs and process requirements, we can produce tailored components, including variations in size, shape, and material composition. This custom approach ensures that the consumables are perfectly suited to a customer’s specific application, optimizing the performance of the PVD system.

Quality Assurance and Continuous Testing

We maintain a stringent quality control process throughout the entire production cycle of its consumables. Continuous testing is conducted at each stage of production, ensuring that the components meet the highest standards. This includes testing for:

Benefits of Using Tinsan Materials PVD Consumables

Tinsan Materials’ range of PVD consumables, including crucibles, boats, and filaments, ensures reliable and efficient performance for E-beam evaporators, ion sources, and thermal evaporators. The custom manufacturing and rigorous quality control processes guarantee that each product is tailored to meet specific requirements, ensuring high-quality coatings and consistent results in thin-film deposition applications.