Sputtering Targets

Sputtering targets are critical components in the sputtering deposition process, a widely used method for creating thin films in various industries, including electronics, optics, solar energy, and coating technologies. This physical vapor deposition (PVD) process involves bombarding a target material with high-energy particles, typically ions from a plasma, causing atoms to be ejected from the target and deposit onto a substrate. At Tinsan Materials, we specialize in providing high-quality sputtering targets that ensure superior thin film deposition performance, helping customers achieve high precision and reliability in their manufacturing processes.

What Are Sputtering Targets?

Sputtering targets are materials, typically made from metals, alloys, ceramics, or composites, used in the sputtering process to produce thin films. These targets are designed in various shapes, such as circular, square, and custom configurations, to meet specific application needs. The target material plays a significant role in determining the properties of the deposited film, such as its electrical conductivity, optical transparency, and durability. We offer a broad range of sputtering targets, including high-purity metals and specialty materials tailored to your specific application requirements.

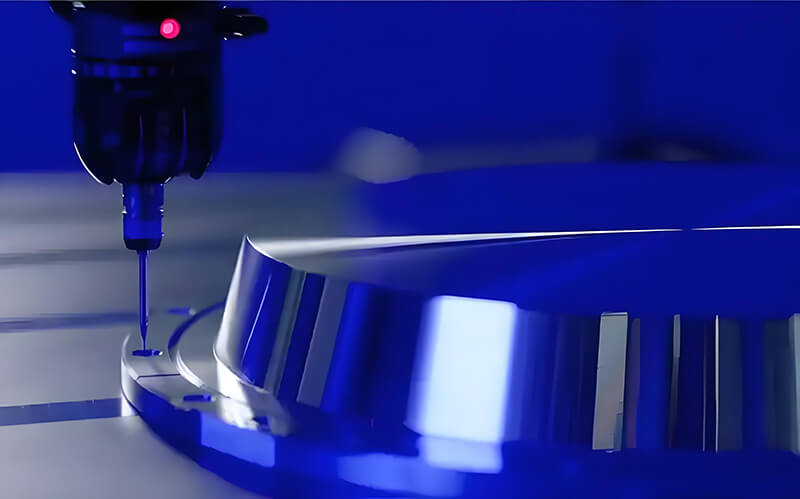

The Sputtering Process

The sputtering process begins by placing the target material in a vacuum chamber, where it is subjected to ionized gas, often argon, to create a plasma. The ions from the plasma collide with the target, causing atoms to be ejected and travel towards a substrate, such as a silicon wafer or metal surface. These atoms then condense onto the substrate, forming a thin film layer. The success of the sputtering process depends heavily on the target’s purity, composition, and surface characteristics. We manufacture sputtering targets with consistent quality to ensure smooth and uniform film deposition.

Why Sputtering Targets Are Essential

Sputtering targets are integral to the production of high-performance thin films, which are essential in industries like semiconductor manufacturing, optics, solar energy, and more. The material of the sputtering target determines the properties of the thin film, including its optical, electrical, and mechanical characteristics. For example, in the semiconductor industry, metals like copper or aluminum are often used for conductive layers, while in solar energy applications, materials such as cadmium telluride or copper indium gallium selenide are used to create photovoltaic layers.

We offer a wide variety of sputtering targets, including pure metals, alloys, and specialty materials, all carefully manufactured to meet the demanding requirements of our customers. Our targets are designed to produce high-quality films with optimal performance in every application.

Our Available Sputtering Targets

Metal Sputtering Targets

Metal Targets are among the most commonly used sputtering targets due to their excellent conductivity and suitability for thin-film applications in electronics, semiconductors, and optics. Metals such as aluminum, copper, gold, platinum, and silver provide reliable film conductivity and reflectivity. Additionally, these metals often achieve high purity levels, which is essential in precision applications such as integrated circuits and microelectronics. We supply high-purity metal targets, ensuring optimal performance in each deposition process.

Alloy Sputtering Targets

Alloy Targets combine two or more metallic elements to achieve specific properties, such as enhanced corrosion resistance, magnetic characteristics, or mechanical strength. Alloys like nickel-chromium, titanium-aluminum, and stainless steel are frequently used in hard coatings, magnetic storage, and decorative films. Alloy targets offer flexibility in tailoring thin films with distinct properties, making them suitable for advanced applications in electronics, medical devices, and automotive components. We provide customized alloy compositions, enabling the precise control needed in demanding applications.

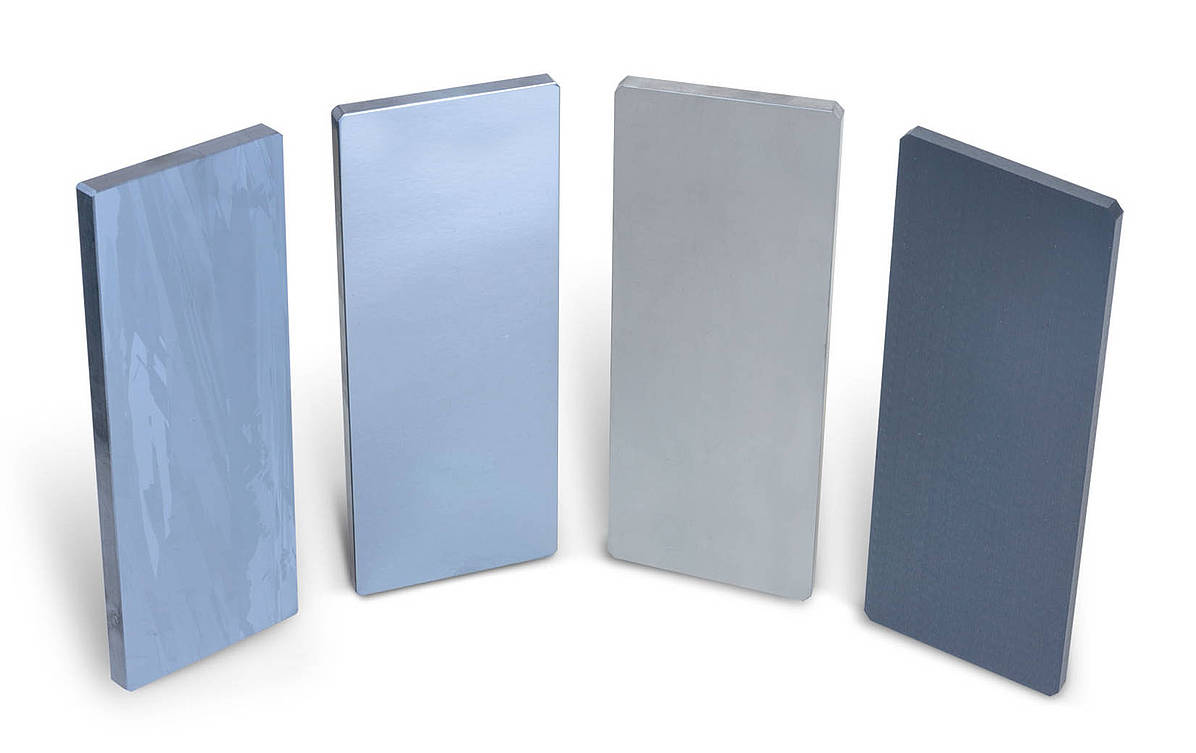

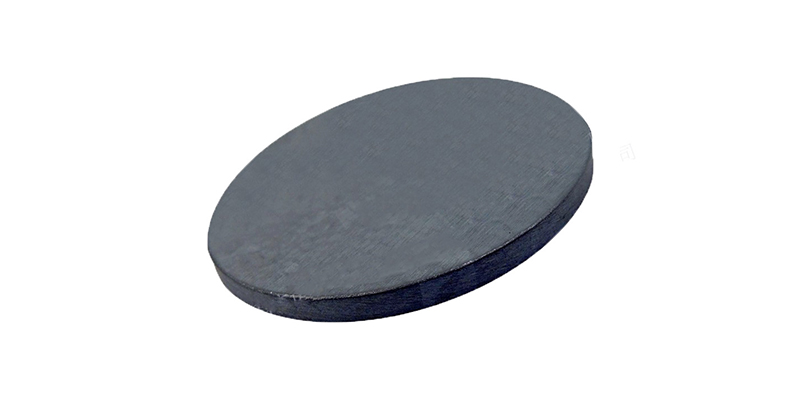

Ceramic Sputtering Targets

Ceramic Targets consist of non-metallic materials that are ideal for applications requiring high wear resistance, hardness, and thermal stability. Materials like titanium oxide (TiO₂), aluminum oxide (Al₂O₃), and silicon carbide (SiC) are commonly used for thin films in optics, wear-resistant coatings, and solar cell technology. Ceramic targets are particularly useful for applications where durability and chemical inertness are critical. We offer a wide range of ceramic targets tailored to meet the needs of industries focused on optics, automotive, and protective coatings.

Types of Sputtering Targets

We offer various types of sputtering targets tailored to different application needs:

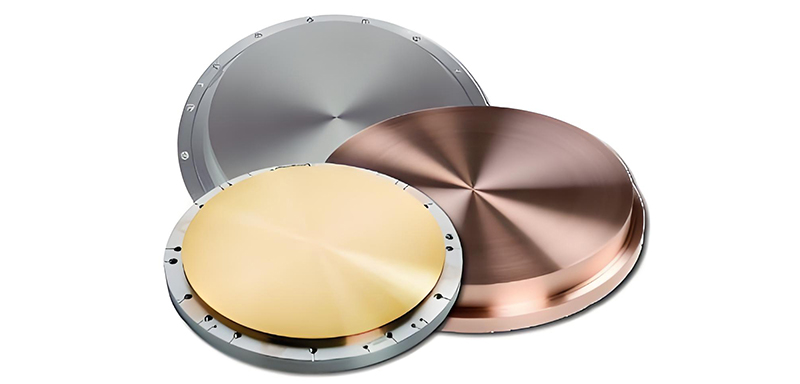

1. Bonded Targets are created by bonding the target material to a backing plate (often made from copper, stainless steel, or aluminum). This design ensures better heat distribution during the sputtering process and enhances the target’s structural support. Bonded targets are ideal for high-power sputtering applications, such as semiconductor and solar cell manufacturing.

2. Rotatable Targets rotate during the sputtering process, ensuring that the sputtered material is evenly distributed across the substrate. This feature maximizes target utilization and reduces the risk of overheating. Rotatable targets are particularly beneficial for larger-scale applications that require continuous deposition processes, such as semiconductor production and optical coatings.

3. Flat Targets are the most common sputtering targets. These are flat plates or discs of material placed in the sputtering chamber. The target material is eroded evenly across the surface, leading to uniform film deposition. Flat targets are versatile and cost-effective, making them suitable for a wide range of thin-film applications.

4. Planar Targets are a type of flat target designed to optimize uniformity and film quality. They are used primarily in the production of microelectronics and optical coatings, where high-quality thin films are required.

5. Circular and Custom-Shaped Targets. Circular Targets are ideal for applications that require circular deposition patterns. These targets are available in various diameters and can be customized to meet specific equipment needs. Custom-Shaped Targets are designed to fit unique sputtering systems, ensuring precise film deposition tailored to specific manufacturing processes.

6. Composite Targets consist of two or more materials combined into a single target. These targets allow for the deposition of alloys or multi-layer films in a single sputtering cycle, providing the benefits of both materials. Composite targets are often used for specialized applications such as hard coatings, decorative finishes, and multi-functional thin films.

Sputtering targets are essential components in the sputtering deposition process, directly influencing the quality and performance of thin films across various industries. Selecting the appropriate target material is critical to achieving the desired film properties. We offer a wide range of sputtering targets, including metal, alloy, ceramic, composite, and specialty materials, all manufactured to the highest standards. Whether you’re working in semiconductor, solar, or coating industries, We are here to provide you with the best sputtering solutions for your needs.